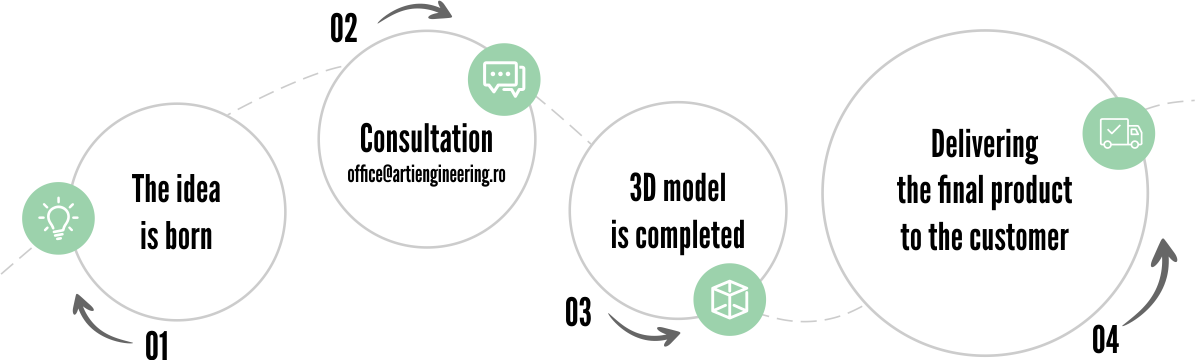

Do you have an idea but you are not yet acquainted with 3D modelling?

No problem, we will help you, because we also undertake modelling. Share your idea with us and we will prepare your model! All you have to do is contact us at office@artiengineering.ro

Have you already prepared your CAD model?

Send it to us at office@artiengineering.ro in stl. format and we will give you an offer for 3D printing. We do not only undertake individual printings, but also small batch production. Contact: office@artiengineering.ro

Is it possible that the model has already been planned?

If you find the design or product you are looking for on the internet, we will print it out. Just browse here: Thingiverse.com

Contact: office@artiengineering.ro

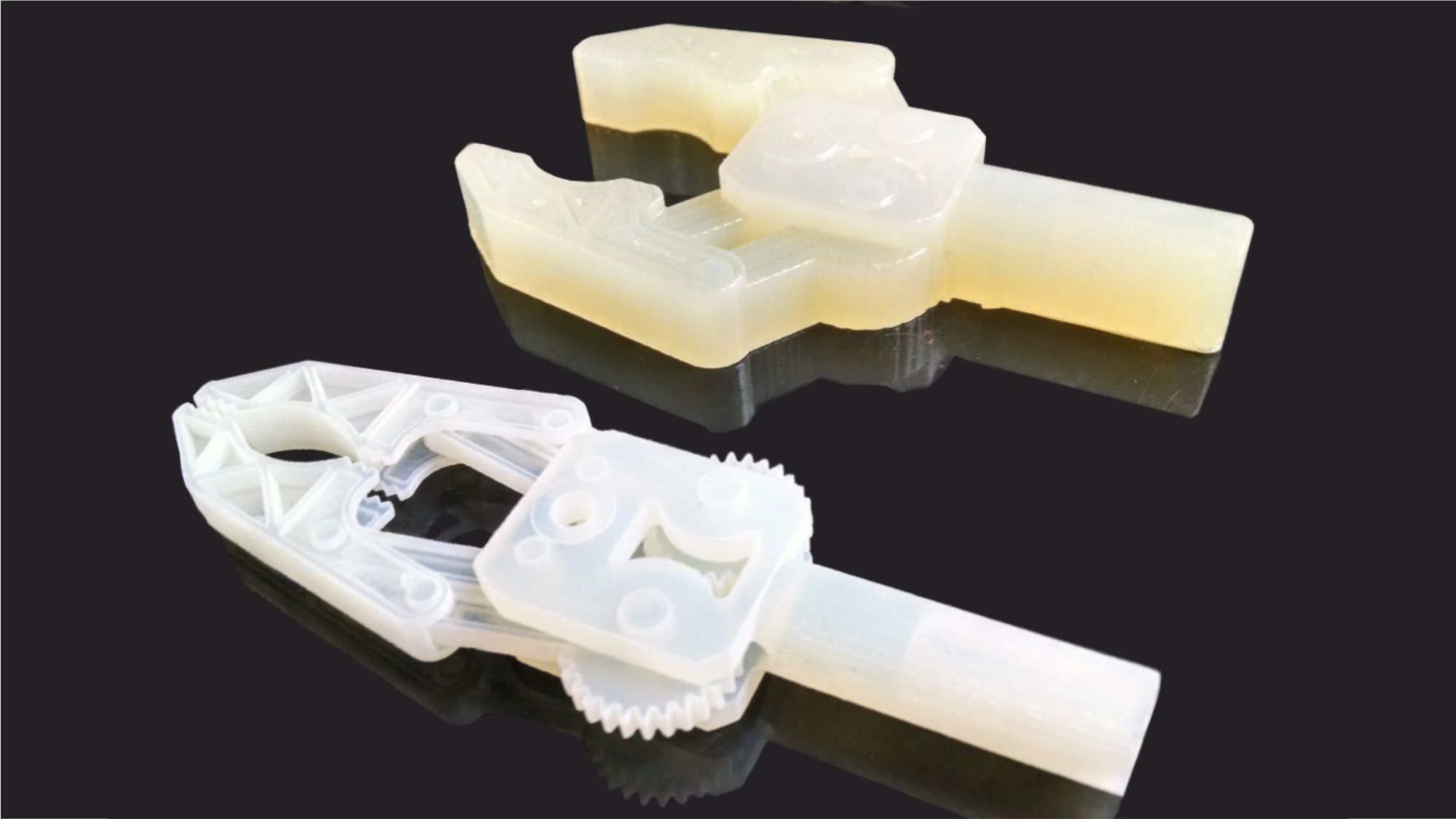

We offer 3D printing of several different plastics and of flexible materials (rubber). Read the material list here.

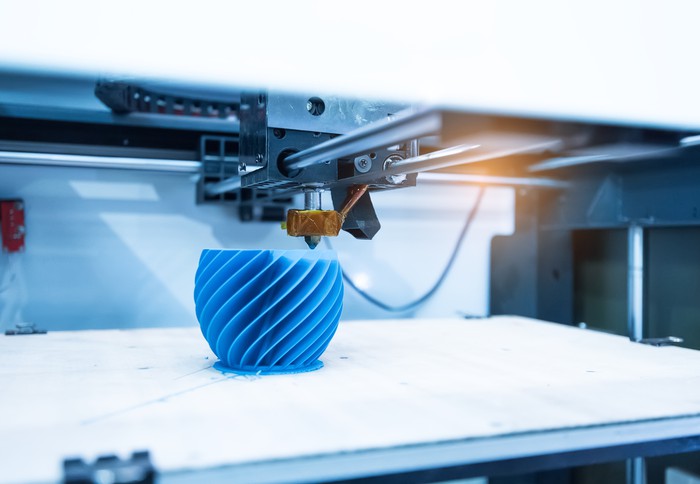

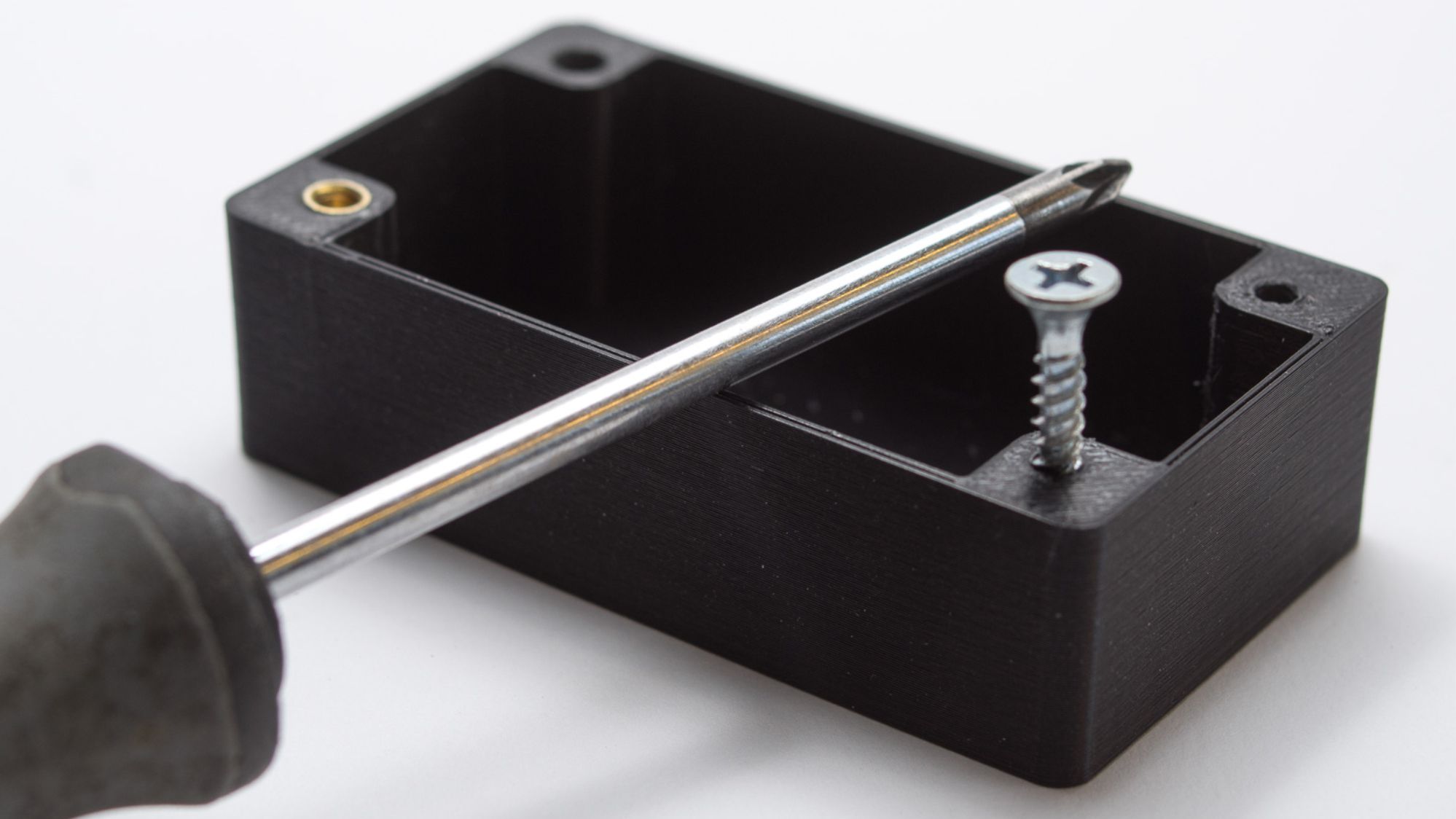

A PROJET MJP 2500 PLUS type 3D printer is used in the manufacture. The maximum size of the pieces to be manufactured is 295 x 211 x 144 mm.

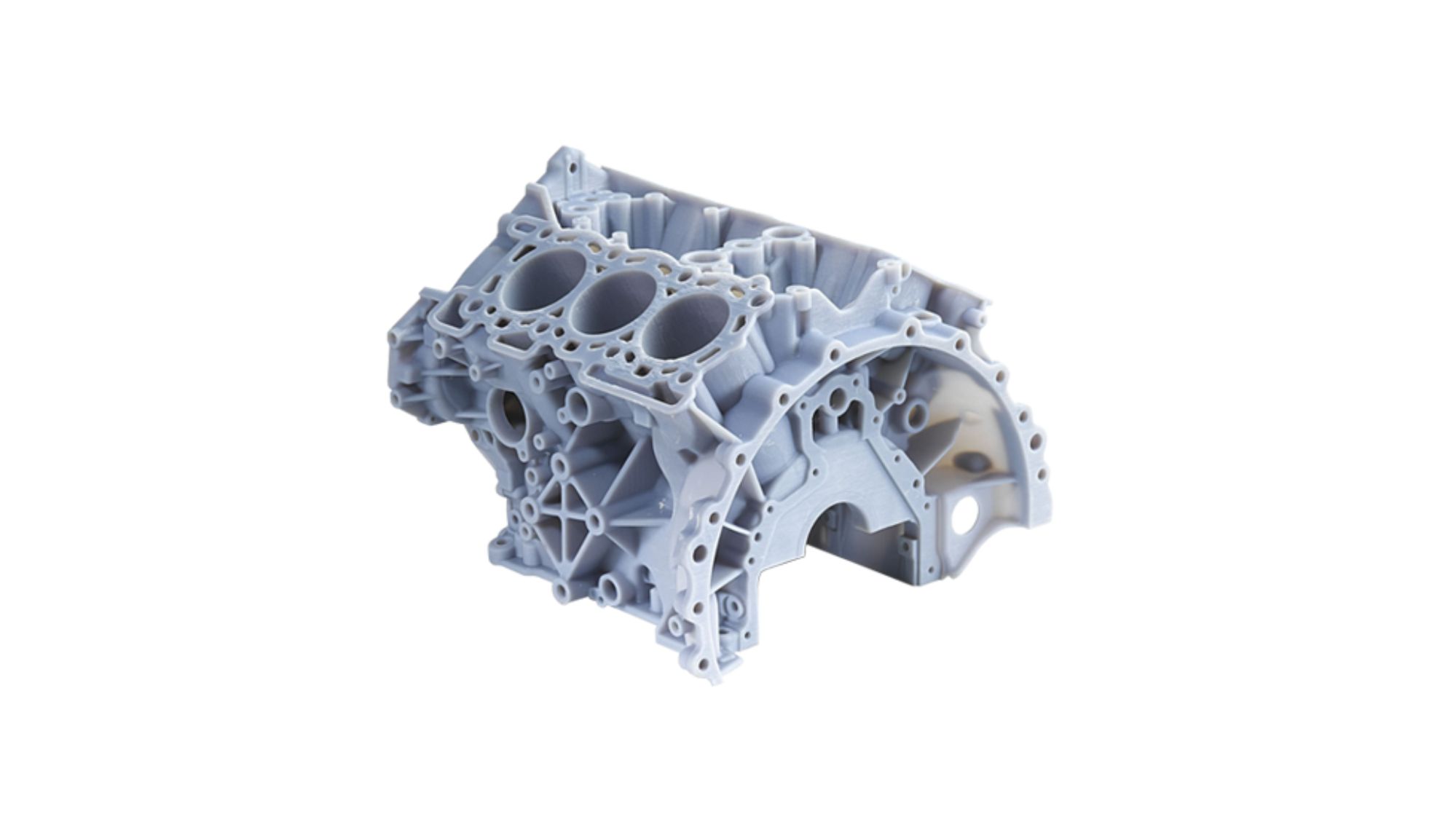

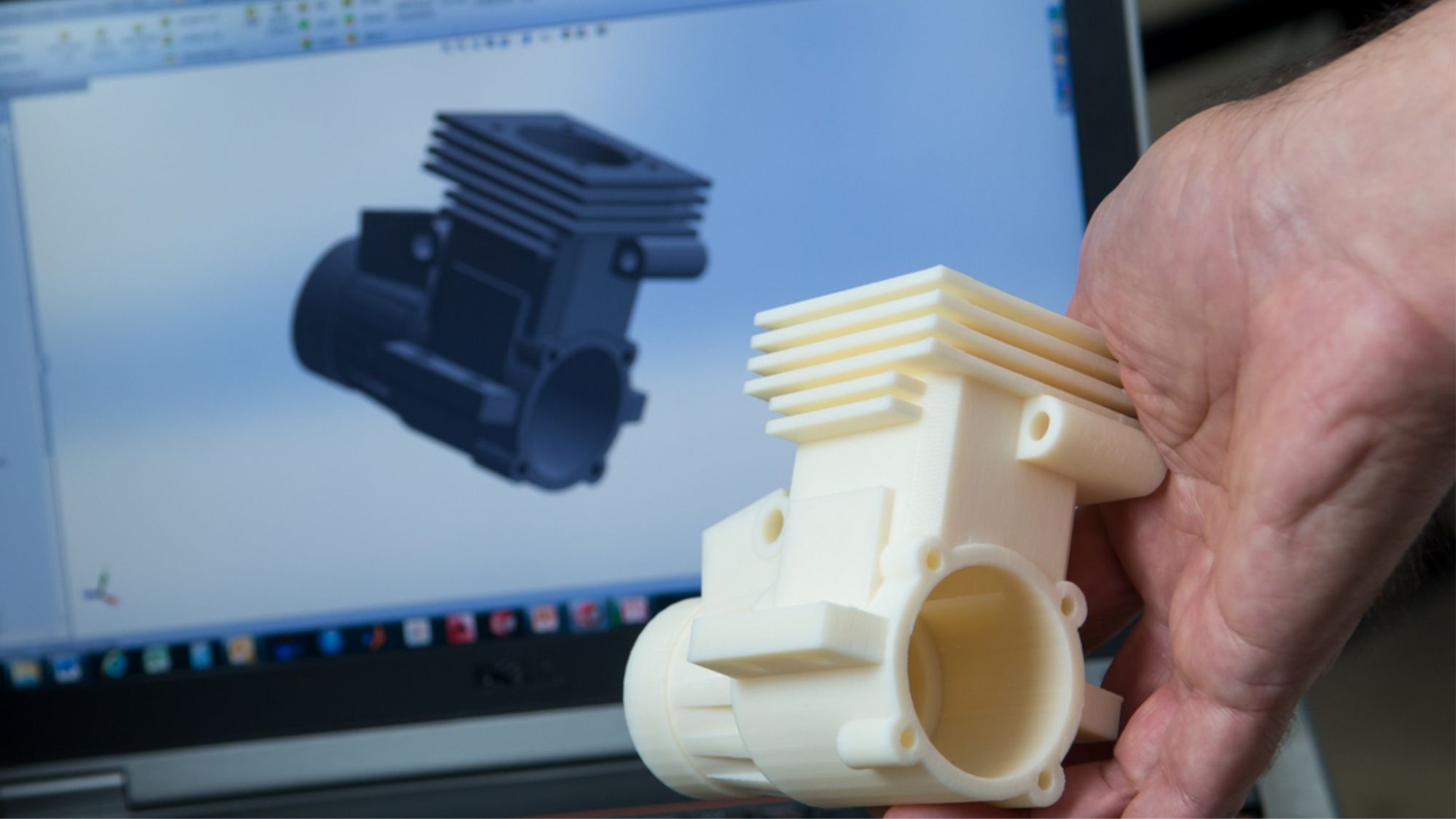

If a prototype is required for production development during the testing phase, then 3D printing is the best choice, because it can greatly reduce the costs.

One of the defining tasks of successful companies is continuous development and innovative orientation. The success of the product is determined in the early stages of design, even though a fraction of the development costs is spent. However, the decisions made at this stage determine 80% of the entire development costs.

Nowadays, 3D technologies have become exceptionally important due to the acceleration of product development cycles. With advanced technologies and raw materials, we have the opportunity to manufacture individual pieces for devices and small product series for finished products in a cost effective way in addition to the prototype components. New opportunities opened up for engineers, product designers, format designers, tool designers and even for doctors and jewellers. With the aid of the lightning fast 3D printing technologies, the dreamed up products can be held in the hands within hours.

WHY IS IT WORTH USING 3D PRINTING IN THE PRODUCT DEVELOPMENT PROCESS?

• Be more innovative. Print prototypes in a few hours, get feedback, customise your design, repeat until the product is perfect.

• Reduce development costs. Find design errors during the process and resolve the issue quickly.

• Production of physical 3D models in a quick, easy and cost-effective way

THE ADVANTAGES OF 3D PRINTING:

• The most costly part of the design process is undoubtedly testing in the trial and error process, testing possible alternatives and experimenting with new materials and forms. This is one of the areas where 3D printing can save us significant amounts of money and time.

• 70-90% of the costs are defined in the early stages of development. This includes design costs and the resources used for subsequent production and testing. Obviously, the faster and easier we can control the design, the less material and time we waste in the development. Prototyping, including 3D printing, is kind of "time wining" in this process.